The Different Types of Concrete Saws and Their Uses

Saws are incredibly versatile tools for cutting a wide range of materials. However, whether you need to cut wood, masonry, or concrete, using the appropriate saw for the job is imperative. In this article, we will explore the different types of concrete saws and their uses so you choose the best option for your next task.

Chain Saws

Chain saws are incredibly useful for tackling concrete cutting when undertaking smaller projects or challenging spaces where a larger machine might not fit. Concrete chain saws differ from the type used for wood because concrete-cutting chain saws have diamond-coated blades and rely on wet cutting. This method differs from dry cutting because it relies on a water system to wet the tool, which also prevents the creation of silica dust. Water also helps prevent the blade from overheating as you use it.

Advantages of Concrete Chain Saws

The mobility and range of movement offered by a handheld chain saw are perfect for targeting those difficult-to-reach areas, such as tight corners and awkward angles. They provide ultimate control and the accuracy needed to complete the job quickly and easily.

This tool also has dust-suppression capacities when used with specialized blades and water feed systems. This minimizes the health hazard of repeated exposure to high-density silica dust particles generated when cutting or drilling concrete.

Circular Saws

Circular saws are another type of handheld power saw used to make precise cuts in various materials. They’re handy for cutting through concrete surfaces, as they have high torque and spinning blades that allow them to cut through hard surfaces.

When using a circular saw on concrete, the blade must be diamond-studded or reinforced to effectively handle the toughness and abrasiveness of the material. By adjusting the speed, angle, and depth settings, craftsmen or contractors can make accurate, straight cuts quickly and easily with circular saws’ powerful cutting features. Working with concrete is no easy feat, but having an efficient tool like a circular saw will help ensure a successful project.

Advantages of Circular Saws

The most noteworthy advantage is a circular saw’s ability to cut quickly and precisely. Additionally, these saws work with various blades depending on the project requirement, increasing their versatility for different types and depths of cuts.

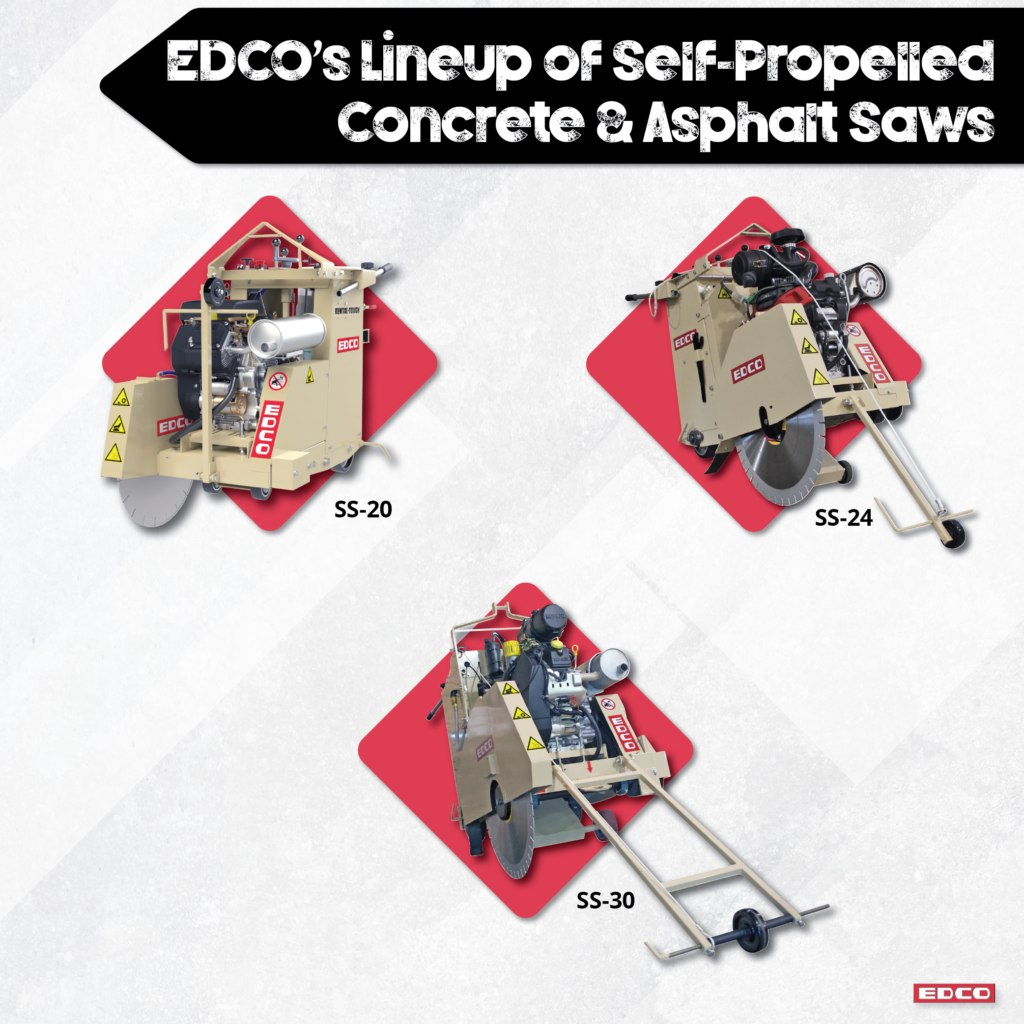

Self-Propelled Saw

A self-propelled saw travels along the concrete surface while rotating saw blades cut into the material at different angles. These saws are ideal for road repair, bridge deck replacement, creating drainage ditches, and other related tasks.

Manufacturers design self-propelled saws with features tailored for the best performance when operating on various surfaces and materials. These saws also allow for greater control and precision when making cuts. Moreover, self-propelled saws also have heat sensors that enable them to work safely without causing overheating or burning of the concrete.

Advantages of Self-Propelled Saws

Self-propelled saws have revolutionized the concrete-cutting industry. They offer many advantages compared to traditional saws, thanks to their wide range of designs, configurations, and features. For instance, with elements such as rubber tires and integrated water systems, self-propelled saws make it easier to maneuver on many types of terrain as you walk behind them.

Learn To Use Your Saw

EDCO offers in-depth video guides on how to use each of our machines. You can review our self-propelled saw training videos within each product description to get a complete understanding of how experts recommend using this tool.

FREE Training 24/7

Get educated & set yourself up for success with EDCOed! EDCOed offers FREE 24/7 training so you can learn at your own pace. Get started now!

Wall Saws

Wall saws can make precise cuts using a diamond blade while avoiding damage to other parts of the structure. You can also configure these saws with a hydraulically powered frame and chuck system. This allows even more precision when making difficult cuts in concrete walls or arches.

The long, thin blades fit through slender openings in walls and ceilings, allowing professionals to cut out sections that block wiring or plumbing. Wall saws offer greater accuracy than traditional concrete-cutting tools and create clean, precise results every time—making them essential for residential and commercial construction projects.

Advantages of Wall Saws

One main advantage of wall saws is their power efficiency. You can use this saw to cut through tough materials. Likewise, wall saws possess adjustable blades that make them suitable for creating highly accurate circular, square, or curved cuts.

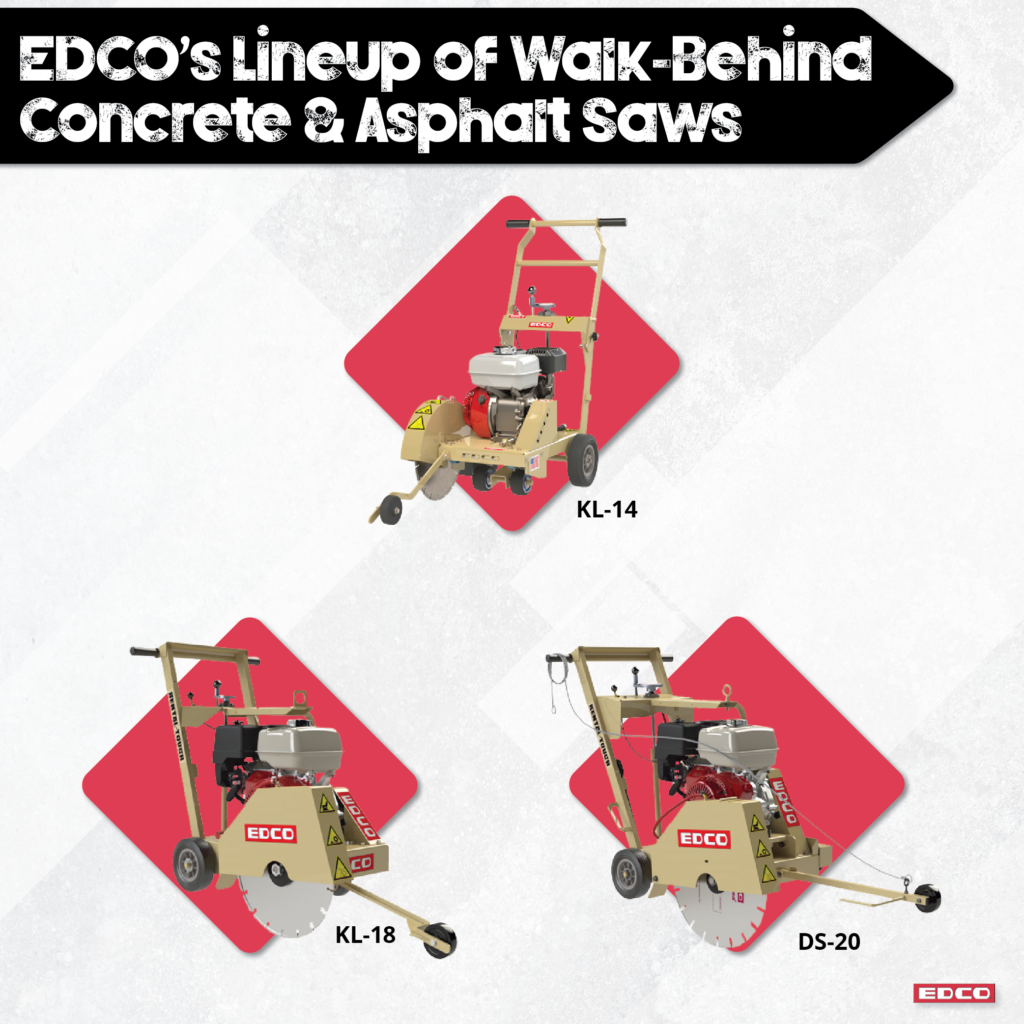

Walk-Behind Push Saws

Walk-behind saws are a must-have for any professional in the construction field. Not only are they ideal for creating grooves in concrete, but they can also be used for trenching and fixing patches. They’re ideal for resurfacing every surface from roads to indoor concrete floors.

This saw option provides excellent control with its left-to-right direction buttons and anti-vibration technology, making them perfect for working on slabs of varying thicknesses.

Advantages of Walk-Behind Push Saws

Walk-behind saws offer tremendous advantages for cutting precise lines. These saws provide a consistent depth and width for all cuts, which is why many professionals use them for road and sidewalk repair. Additionally, these saws have an adjustable guide handlebar, so minimal pushing is required when cutting concrete. As a result, they reduce physical strain when completing a task.

Safety Tips When Cutting Concrete

Understanding the different types of concrete saws and their uses ensures you utilize the ideal tool for the job. This improves safety for workers as it gives them a better understanding of the machines they rely on. To keep workers safe, you also need to use either wet cutting or an industrial vacuum when dry cutting. Avoiding long-term exposure to dust from concrete by wearing a respirator is also essential for safety purposes.

Always wear protective equipment such as gloves, goggles, earplugs, and dust masks. Additionally, carefully inspect the area in which you will be working.

Learn More at EDCO

Equipment Development has training videos, user guides, and spec sheets on all our products. Use our resources to learn how to safely use your saw. Nothing is more important than teaching our customers how to use our concrete saws! Please contact our team if you have any questions about how to use our products. Keep concrete cutting safe and efficient.