The EDCO Edge (The Importance of Choosing EDCO Diamond Tooling)

Advantages of diamond tooling products means nothing without the quality and consistency to help customers achieve their project goals.

The benefits of using diamond tools on the jobsite are endless. Diamond is known as the hardest substance in the world and it also possesses other qualities that make it a prime candidate for use in concrete cutting and grinding. They are ideal for grinding asphalt, asphalt over concrete, stone, pavers, brick, block, granite, marble, porcelain, ceramic tile, glass, glass tile and metal.

With all their uses, customers rely on these materials to get their jobs done quickly and efficiently. It’s important to know that not all diamond tooling equipment is created equal however, and sacrificing quality for price could end up costing you more in the long run.

Many customers don’t know the value of repeated replacement on their diamond tools until these costs start to add up. When looking for an equipment and parts partner, you can rely on EDCO to give you a competitive edge over other suppliers due to the quality and reliability of our equipment.

Diamond grinding tools are proven to outlast their counterparts. When choosing EDCO diamond tools for your equipment, you’ll immediately notice a consistent shape and higher-quality diamond over other brands. But beyond that, we have tested and field-proven our diamond tools to last longer than our competition, providing you a better value for your money.

A Better Build from the Beginning

Choosing the correct bond based on aggregate is key. You want to be sure you are partnering with manufacturers that produce consistent quality. Those that insert inferior, cheaper bond material as filler to reduce price does both the customer and applications injustice. The customer may pay a cheaper price because the manufacturer utilized less expensive matrix material in lieu of what the specification requires, but the life expectancy suffers. Usable diamonds fall out prematurely. This is wasteful, reduces productivity.

Creating a better and more consistent bond to improve product lifecycle takes time, effort and a more involved manufacturing process. All of which EDCO commits to when creating a superior product.

During our manufacturing process, we sinter the material at around 800° C for less than 30 seconds. Other products use a very basic bond powder which needs to be sintered at approximately 900° C for around 15 minutes. These higher temperatures for an extended duration can affect the outcome and quality of the product.

While other companies produce 10-15 segments at a time, EDCO uses a higher quality alloy metal powder during production for better diamond retention and consistent production, one segment at a time. This leads to a longer-lasting lifespan for the tool.

We Pay Attention to Detail – Size, Concentration & Grit:

As we mentioned above, not all diamond grinding tools are built the same. EDCO tooling uses a strong 27% diamond concentration. When you compare that to the 15-18% finer concentration others tools use, EDCO’s diamond tools are built to outperform. Using a finer diamond can make it appear like more diamond is in the segment than actually is (when broken down to parts per karat). These tools will most likely wear out much faster than the EDCO brand.

Grit also matters. The grit number indicates the size of the abrasive grains used when making a grinding segment and dot or button. The grain sizes range from coarse to very fine and EDCO’s diamond tools will also outperform in terms of grit. When comparing to similar products, we found that other manufacturers marked with an #18 grit were mostly made of #30/40 grit, while rounds marked #30 grit were actually 40/50 grit. It’s important to note that true #16/18 grit diamond mesh is much more expensive than #30/40 and the finer grits EDCO provides bring extra value to our customers.

This is important as other manufacturers use this as a bait and switch tactic when marketing their tooling. They label their packaging as one item that is a bit more expensive, but actually insert less expensive materials. It’s extremely difficult to test each piece, which is why it’s always best to partner with a vendor like EDCO that has your back. Our integrity is on the line, thus we are only putting our name on quality, accurately manufactured tooling.

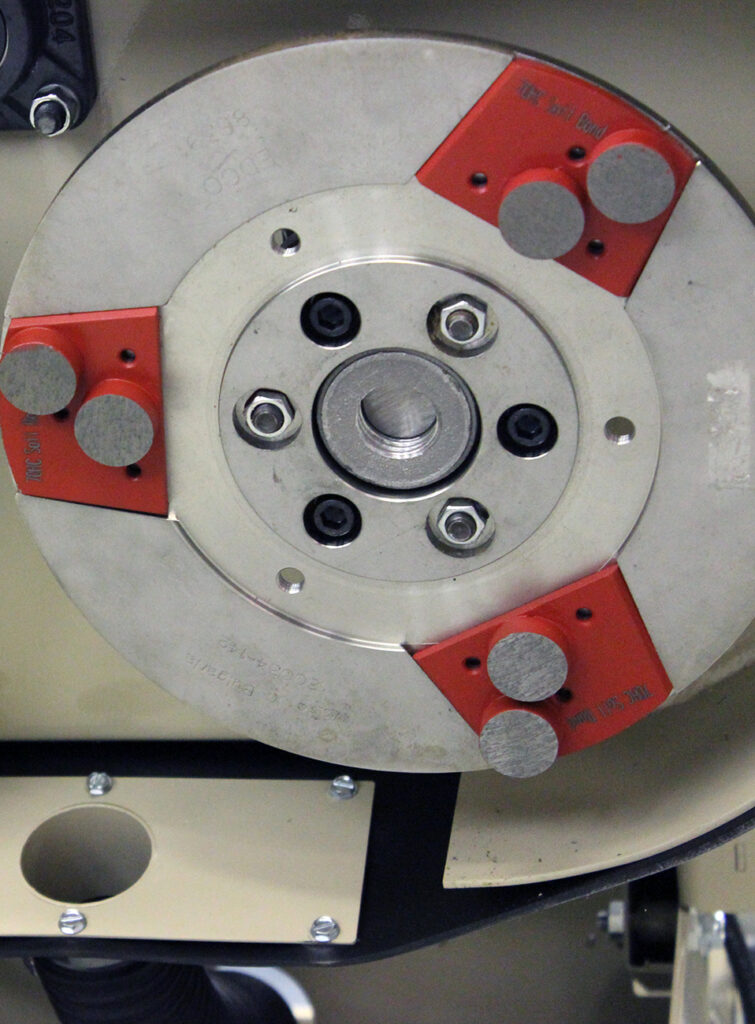

Finally, we don’t cut corners when it comes to true product size. Our EDCO Magna-Trap Diamond Tooling is 10 x 10 x 40mm. When compared to similar product samples, some claimed to be 40mm but actually measured 39.5mm long. EDCO rounds are 26mm wide x 10mm tall, and other samples measured 25.5mm x 9.5mm.

While this may not seem like a huge difference, EDCO knows that sizing matters and we don’t skimp to save cost.

Reliable Replacements for Peace of Mind:

In the event you need to get replacement parts fast, EDCO has you covered with fast shipping and packaging that ensures your products get their intact and ready to work. We offer free shipping on our orders and even a next day shipping option for when you need it fast.

The Training to Succeed:

Not only will using EDCO Magna-Trap Diamond Grinding Tooling products give you an immediate edge on the jobsite, but our team also backs up our products with industry leading training and education.

We go the extra mile to make sure our customers know how to correctly use our products so that they are getting the most out of their investments. Trust the EDCO Edge and know that you’re using the best tools and methods that will add an extra layer of quality to any project.